How to Replace Rudder Return Springs

Rudder return springs occasionally break. I had two fail on me in

about 1500 hours. One on the ground and one during the takeoff roll

at Harris Ranch - that did get my attention.

The tricky part in replacing these springs is that they need to be

stretched quite a bit to get hooked in. On top of that, they tend to

be not in the most accessible places.

The following trick makes this repair pretty easy - at least it's

worked great for me twice.

- Figure out how much stretch is needed in the spring to get it

hooked into the attach points. That's a bit shy of 3/4 inches for my

Grumman.

- Get two stacks of washers of that hight.

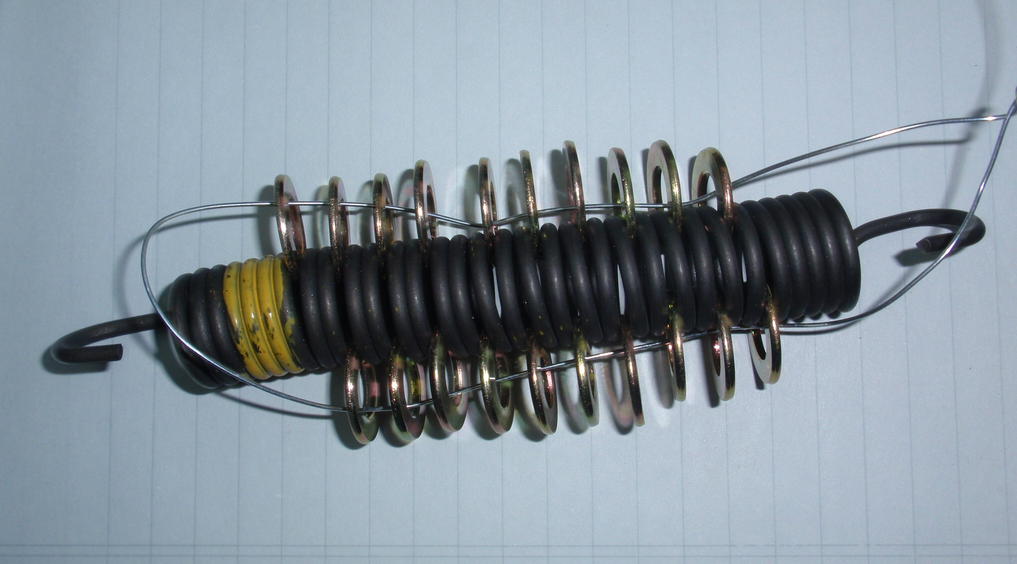

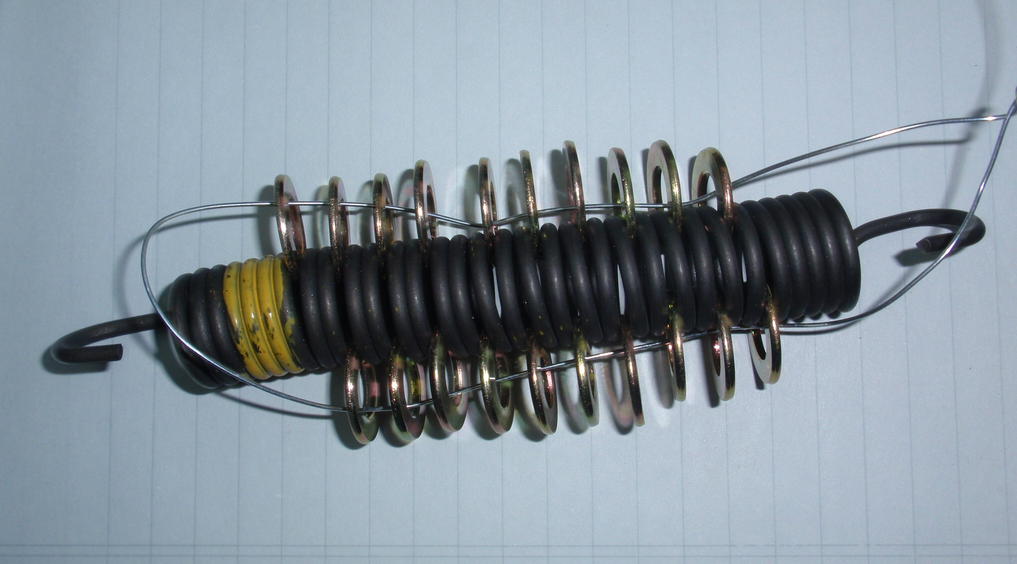

- Insert the washers into the spring as shown in the pictures. This

is easy to do by bending the spring. Put one row on either side so the

spring is straight. Also make sure the hooks don't face the washers.

That way you can still bend the spring in the direction of the hooks,

which you need to do to hook it, without loosing the washers.

- Feed some safety wire through the washers or else you'll be

searching for washers in the belly of your plane for weeks.

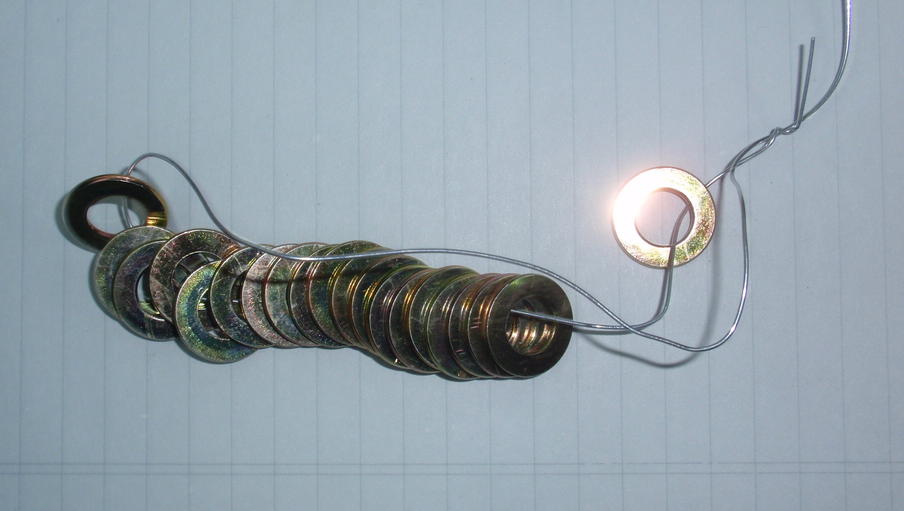

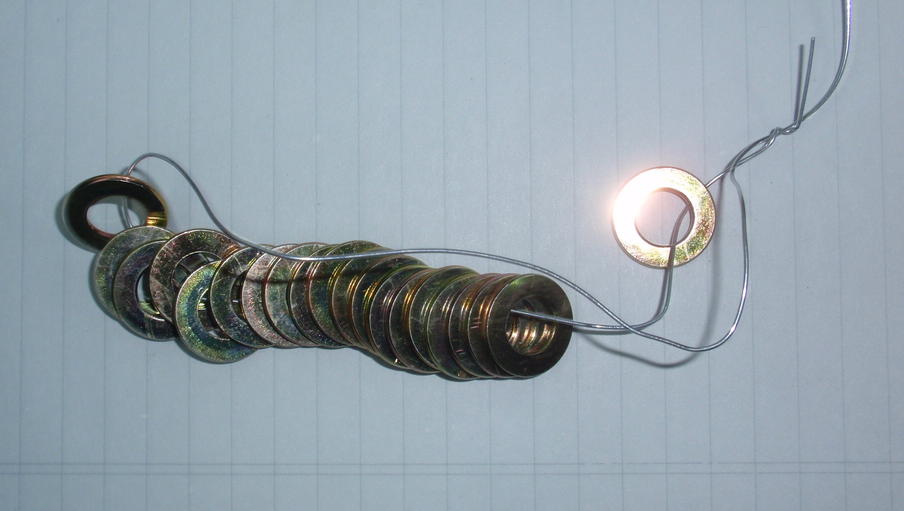

- Hook the spring on the hard to reach end first. The Grumman

springs have two different hooks, one is bent 180 degrees, the other

slightly less. The latter one is the one you insert last since it

requires less bend in the spring.

- Hook the second end of the spring. In the Grumman this is a

simple matter of aligning the hook with the hole and pressing the on

the spring so the hook opens and slides in place.

- Push on the rudder pedal and retrieve your washers.

©2010 EAA Chapter 62

Questions and Feedback can be sent to the

webmaster