Home Builder's log

Andy Werback's Legacy Project

: Working on the rudder and elevator/horiz stab

03 - 31 - 2005

Well, lots of sanding. The rudder, elevators, horizontal stab and the interface between the h stab and vert stab get a lot of micro and sanding, fit checking, realignment of one rudder hinge. Finally, everything fits and moves smoothly, good clearance. Installed the final BIDs on the rudder and vertical stab after rebuilding the lower end of the rudder.

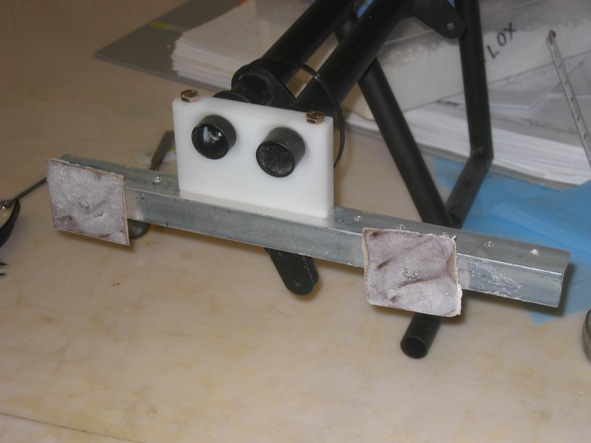

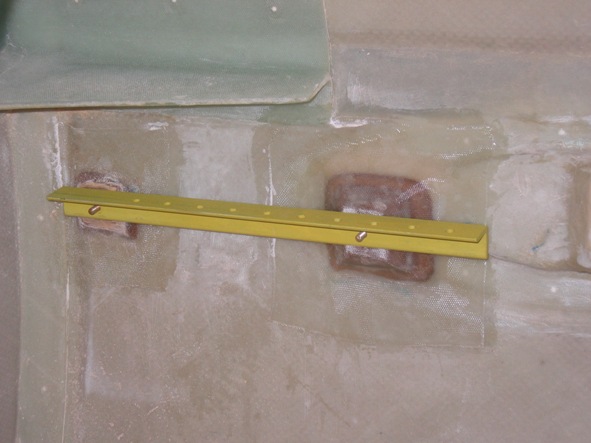

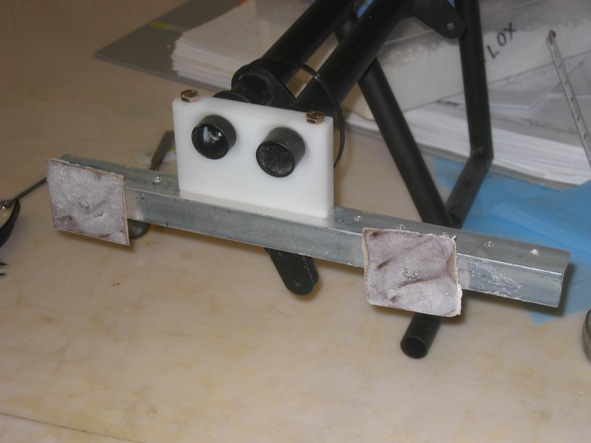

Other work included building a frame/mounting for the rudder bars around the firewall/engine mount.

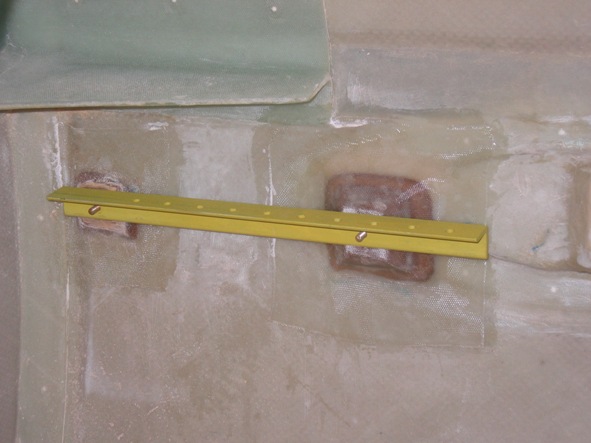

Starting the supports for the rudder bars. Aluminum angle with a hole pattern to allow adjustment

Installing phenolic supports for the 10-32 bolts with flox. Everything is leveled and square

A coat of primer and it looks like it should do it. BIDs are installed

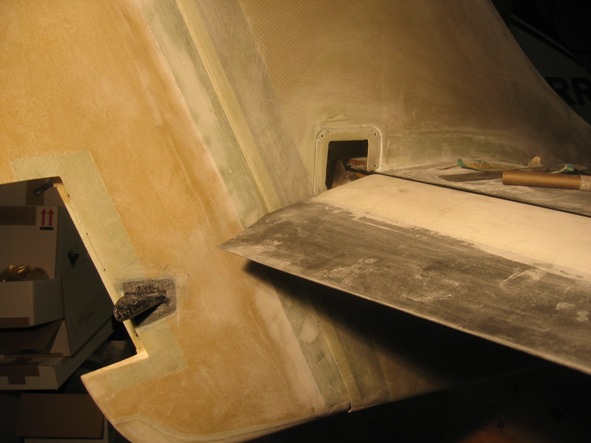

Test fit - an adjustable clevis is going to connect the rudder cable to the pedals

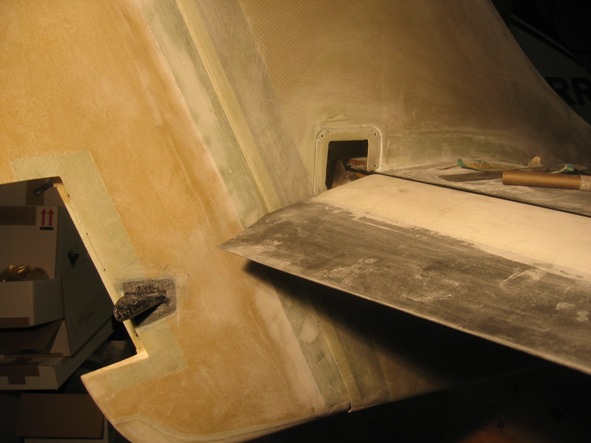

Now to work on the foam and add micro to make a smooth transition from the horz stab to the elevator

Test fit, micro, sand, repeat

Also work on the access panel cutout

Adding micro with the heat gun to make it go on smoothly. This all turned out well, but lots of work was required (pretty much normal for this stage!)

Home Builder's log

All content not otherwise protected is © 2004 - 2024 by Andy Werback

EAA Chapter 62 provides this builder's log as a service to its members so that those who would like to build an

aricraft can learn from those that do.

Questions and Feedback can be sent to Webmaster.

Web hosting donated by Hurricane Electric.