First item is to remove the original air inlet hole and cover it over, maintaining strength. A diamond pattern was added using foam and another layer of BID

Then we had to rework the aft nose gear fairing to make it large enough to cover the nose gear aft support

Sure looks better with its clothes on

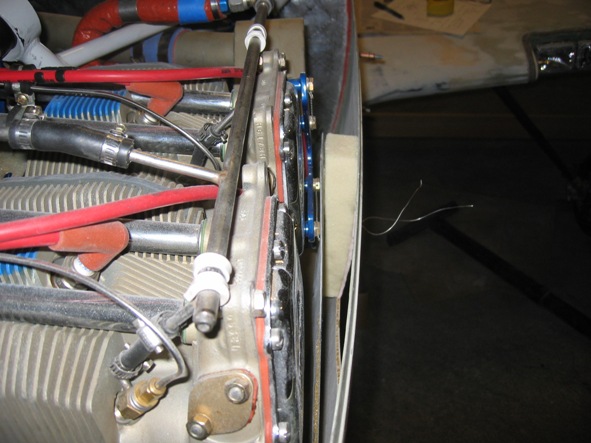

This is the initial setup for the intercooler inlet. Thanks to Don Barnes for the helpful carbon shapes

I think there's not a lot of room for this inlet - about 1 inch is all there is

The NACA inlet for the intake air has been cut out and the new inside piece is temporarily held in place. Next step is to BID the sides

Building up the air box around the oil cooler; Using shaped foam inside for a form

Letting it cure with stuff on the outside to hold the BID in place

The NACA inlet and its air filter

Building up the inner part of the air box. This has an alternate air door and the hose to the turbine

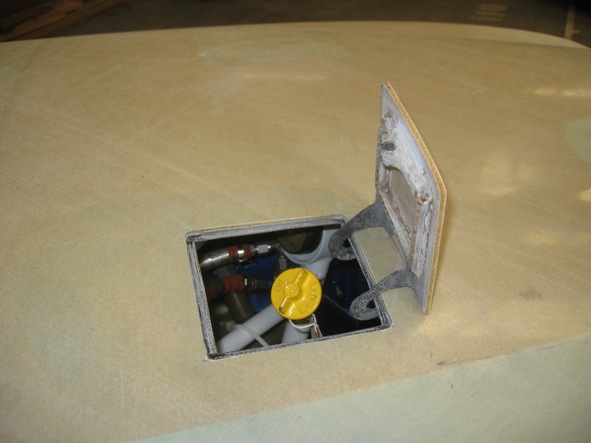

Building up the oil access door. The hinges and closing pin were installed before cutting the door out from the cowling

Hey, it might even work. At least it wasn't 3 inches off somewhere else

Sorry, slightly out of order - installing the nose strut fairing. Might have installed it too far forward (in order to clear the Schrader valve)

Last but not least, Thanks Rich and Mike for putting the canopy back on. It fits now that the engine weight is on the fuselage